What are the advantages and disadvantages of stainless steel yacht anchors compared to traditional anchors?

Advantages of Stainless Steel Yacht Anchors

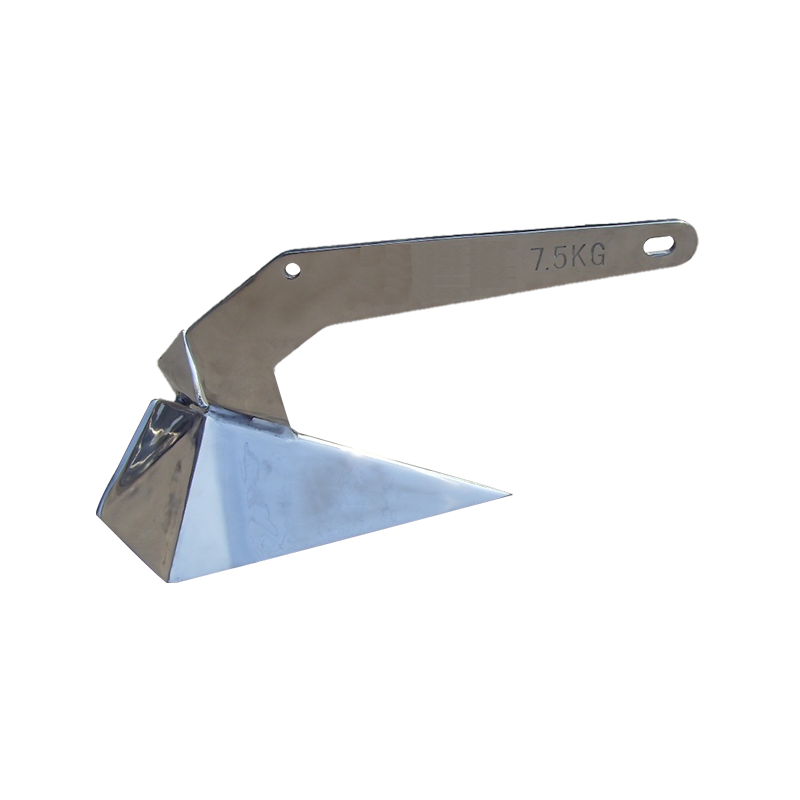

Stainless steel, as an alloy, offers high corrosion resistance and mechanical strength. In marine environments, saltwater corrosion places high demands on anchor materials. Stainless steel yacht anchors, containing elements such as chromium and nickel, form a stable passivation film, effectively resisting corrosion in seawater. This corrosion resistance ensures a long service life in salt spray and humid environments.

Traditional anchors are often made of carbon steel or ordinary steel. While strong, they lack corrosion resistance and are prone to rust and damage. Therefore, traditional anchors often require additional corrosion protection, such as coating or galvanizing, to slow the corrosion process. Stainless steel anchors have a smooth surface finish, making them less susceptible to the accumulation of algae and other marine life, simplifying cleaning and maintenance.

Comparison of Mechanical Properties and Structural Design

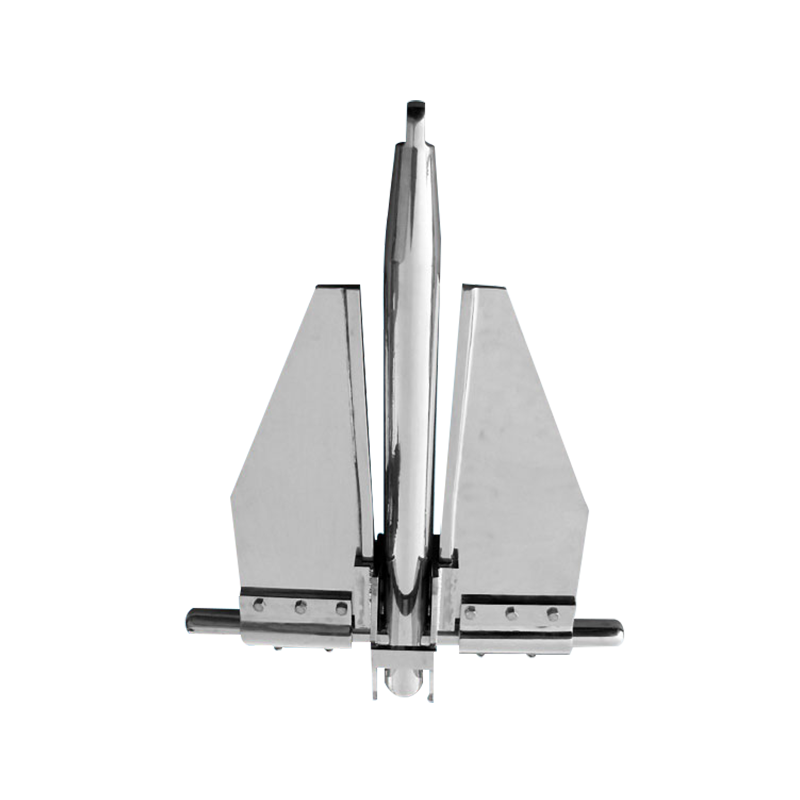

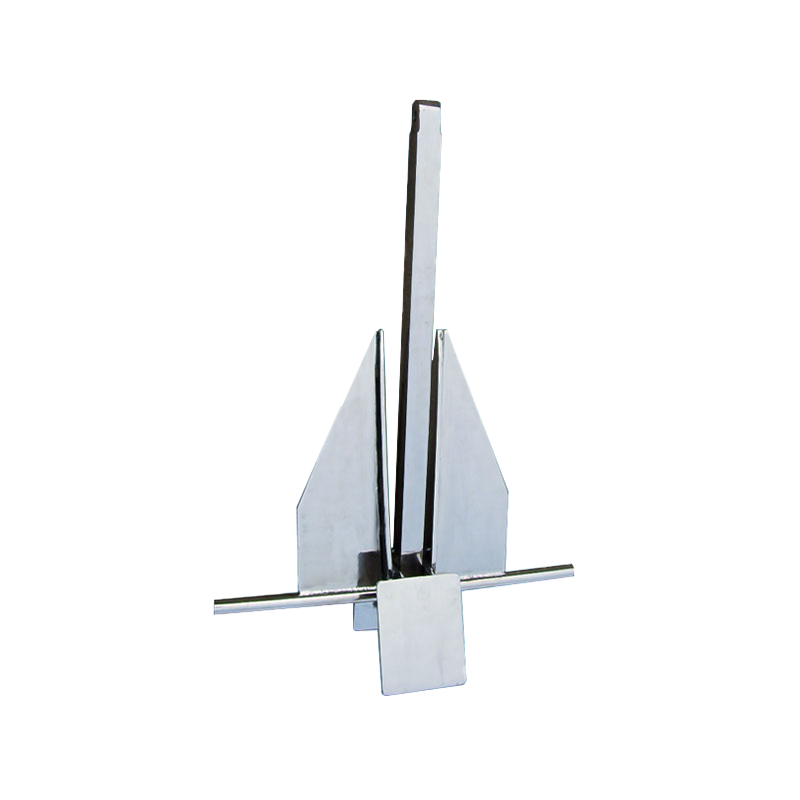

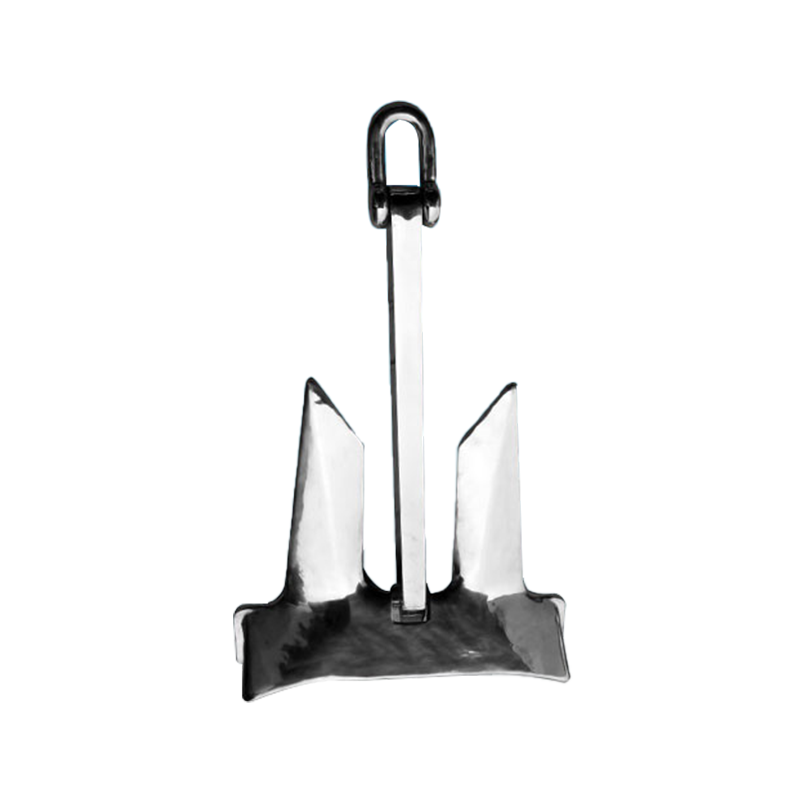

The mechanical properties of stainless steel, including strength, toughness, and wear resistance, directly impact the anchor's grip and impact resistance. High-quality stainless steel yacht anchors typically utilize precision machining to ensure a uniform anchor structure and secure connections. Traditional steel anchors, due to their mature manufacturing process and diverse shapes and structures, offer excellent anchoring performance. Some traditional anchor types, such as the claw and talon types, have become more sophisticated through long-term use.

Stainless steel anchors may be slightly inferior to some high-strength carbon steel anchors in terms of strength. Careful selection of the appropriate anchor type and thickness is crucial to ensure safe use, especially when subjected to extreme loads. Stainless steel anchors rely more on the corrosion resistance and aesthetics of their material, while traditional anchors offer advantages in strength and design diversity.

Ease of Use vs. Weight Comparison

Stainless steel yacht anchors typically feature a superior surface finish and smoothness, reducing wear on the anchor chain and deck equipment. Due to the higher density of stainless steel, anchors of the same size may be slightly heavier than traditional steel anchors. This can affect handling and deployment in some cases. Traditional steel anchors can be tailored in weight and shape to suit different vessel types, depending on the manufacturing process. Lighter anchors are easier for crew to handle, but may lack sufficient holding strength in extreme environments. Stainless steel anchors require less maintenance and have a longer service life, reducing the risk of downtime and repair work due to anchor failure. The following table compares the basic performance of the two anchor types in terms of weight, corrosion resistance, and maintenance frequency:

| Item |

Stainless Steel Yacht Anchor |

Traditional Steel Anchor |

| Material Density |

Higher |

Slightly lower |

| Weight |

Slightly heavier for the same size |

Slightly lighter for the same size |

| Corrosion Resistance |

Better corrosion resistance in saltwater |

Requires anti-corrosion treatment, prone to rust |

| Maintenance Frequency |

Lower |

Higher |

| Service Life |

Relatively longer |

Varies depending on anti-corrosion treatment |

| Surface Finish |

Smooth, reduces friction and fouling |

Rougher, prone to fouling |

Economic Benefits and Purchasing Considerations

In terms of procurement and operating costs, the initial price of a stainless steel yacht anchor is generally higher than that of a traditional steel anchor. This is primarily due to the higher cost of stainless steel and the more complex processing. Over the long term, the corrosion resistance and low maintenance requirements of stainless steel anchors may reduce overall maintenance costs and replacement frequency. They are particularly suitable for yachts and small leisure boats that value aesthetics and durability.

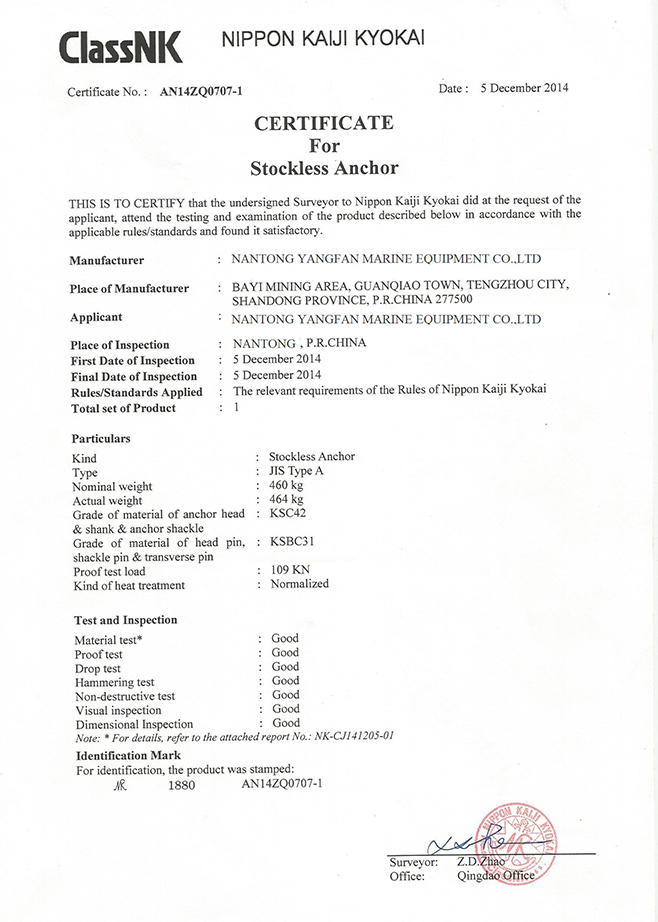

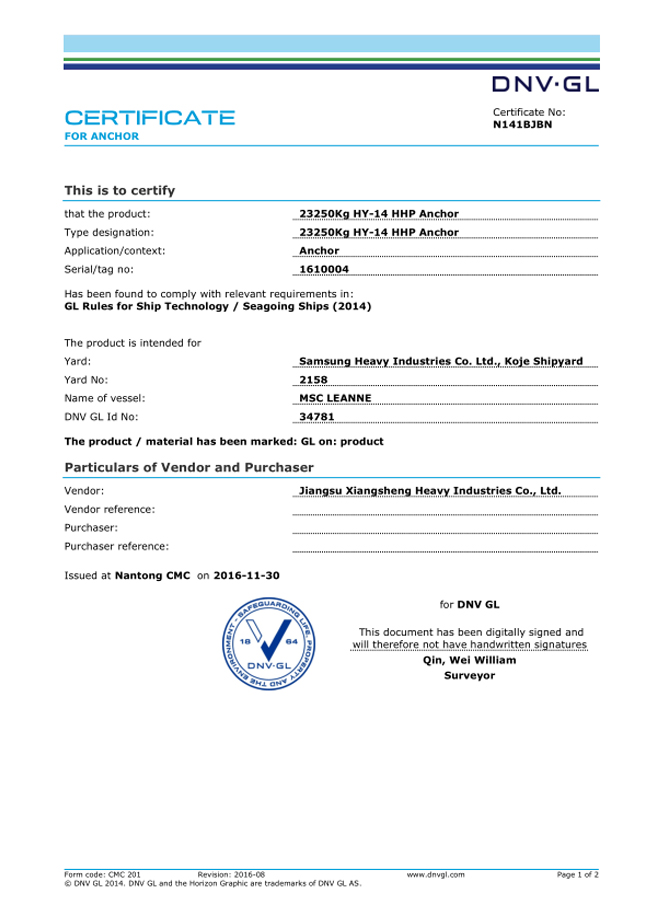

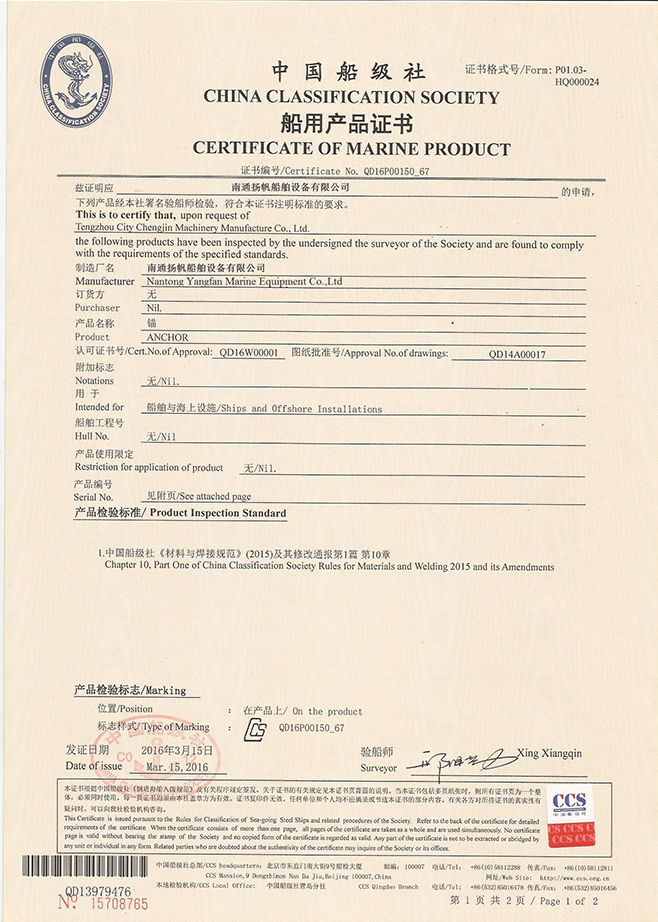

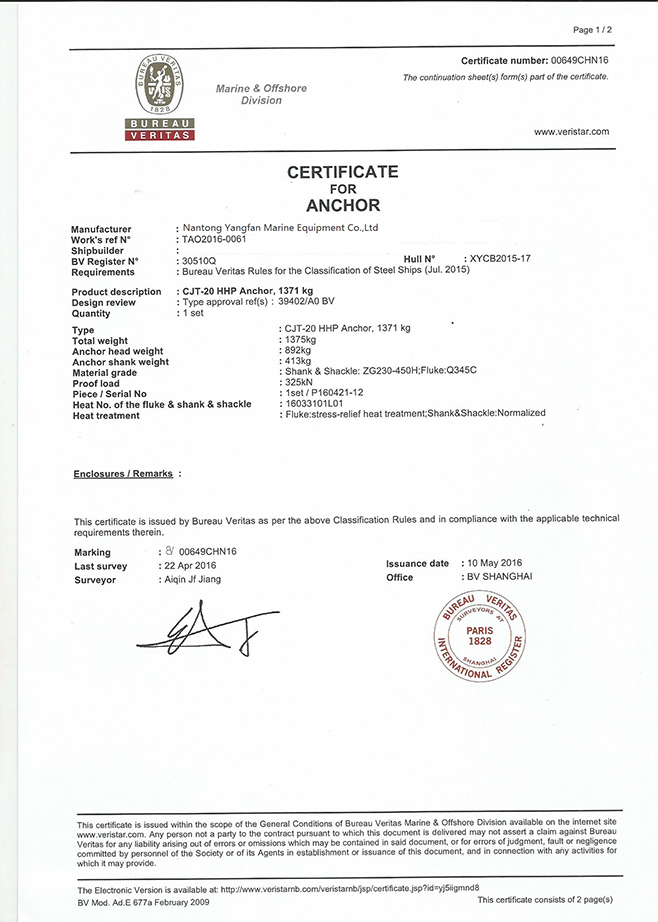

Traditional steel anchors are relatively affordable and suitable for commercial vessels with limited budgets or high-intensity use, but regular maintenance and anti-corrosion measures should be considered. When purchasing, consider anchor certification and compliance with relevant international standards, such as ISO or the American Bureau of Shipping (ABS), to ensure performance and safety.

Application Environment and Applicability

Stainless steel yacht anchors are suitable for both saltwater and freshwater environments and are particularly suitable for yacht owners who prioritize aesthetics. Their corrosion resistance and anti-fouling properties ensure stable performance in a variety of seabed environments. Traditional steel anchors, due to their wide variety and competitive price, are widely used in large vessels and industrial vessels. For vessels that must withstand extreme loads, traditional high-strength steel anchors remain a common choice. Choosing the right anchor should be based on a comprehensive consideration of vessel type, anchoring environment, and frequency of use.

Differences in Maintenance and Care

Stainless steel yacht anchors, due to their high corrosion resistance, typically require only routine cleaning and inspection, resulting in minimal maintenance. Regular flushing of the anchor, removal of debris, and inspection of the integrity of the hook and connecting components are sufficient. Traditional steel anchors require regular maintenance with an anti-rust coating and repainting to prevent rust from developing and affecting anchor strength. Severe rust requires prompt replacement of components to avoid safety hazards. In terms of maintenance cost and time, stainless steel anchors are relatively more economical and time-saving.

Stainless steel yacht anchors offer advantages in corrosion resistance, aesthetics, and longevity, making them suitable for yacht owners with demanding requirements for their equipment. The stability of their material ensures longer-lasting performance in marine environments, reducing maintenance burdens. Traditional steel anchors offer flexibility in price and strength design, making them suitable for commercial and large vessels with high anchor capacity requirements. Furthermore, their mature manufacturing process and diverse product range meet diverse anchoring needs. When choosing, users should consider the characteristics of their own ship type, usage environment and budget, weigh the advantages and disadvantages of the two anchors, and choose the anchor product that best suits their actual needs.

English

English 中文简体

中文简体