How HDG Yacht Anchors Contribute to Yacht Performance and Stability

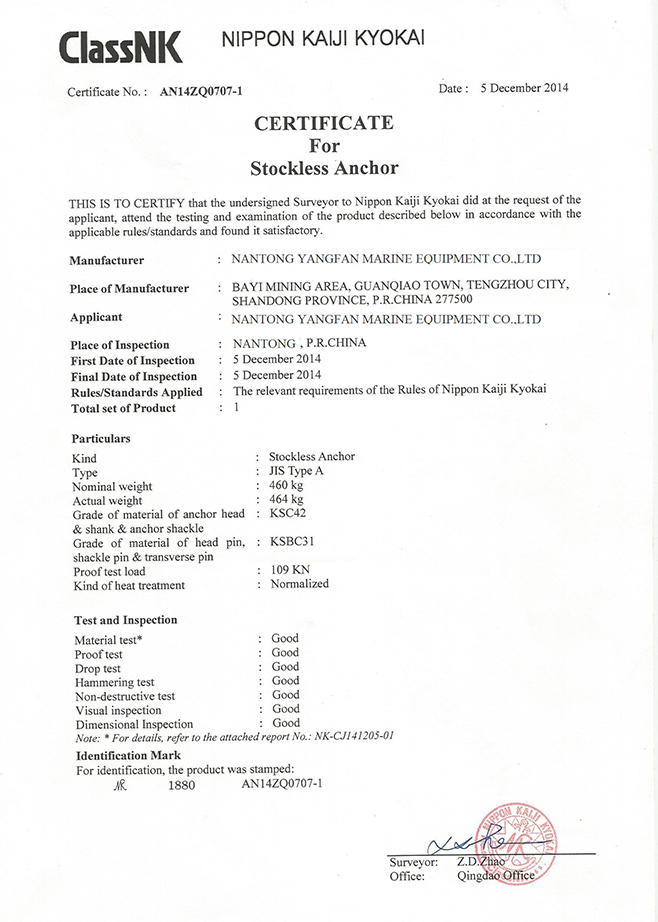

In the marine industry, corrosion is one of the leading causes of anchor failure. Saltwater, humidity, and other environmental factors significantly accelerate the deterioration of metal components. Hot-dip galvanization (HDG) is an advanced process in which the anchor is coated with a layer of molten zinc, providing an exceptional barrier against corrosion. This zinc layer bonds tightly to the steel of the anchor, forming a durable protective coating that resists the aggressive effects of seawater. The zinc coating plays a critical role in preventing rust and degradation, which would otherwise lead to the anchor losing its strength and reliability. Without this protective layer, anchors would be prone to rusting after repeated exposure to saltwater, weakening the material and making it more susceptible to failure. The HDG process also reduces the need for ongoing maintenance, as yacht owners no longer need to worry about frequent repainting or corrosion-related repairs. This results in a longer lifespan for the anchor, making it more cost-effective in the long run. Nantong Yangfan Marine Equipment Co., Ltd. ensures that all of our

HDG yacht anchors are treated with the highest standard of galvanization. The quality of our anchors means that we can deliver a product that performs consistently and reliably, even in the most challenging environments. By improving corrosion resistance, our HDG anchors maintain their functionality for extended periods, giving yacht owners peace of mind during their voyages.

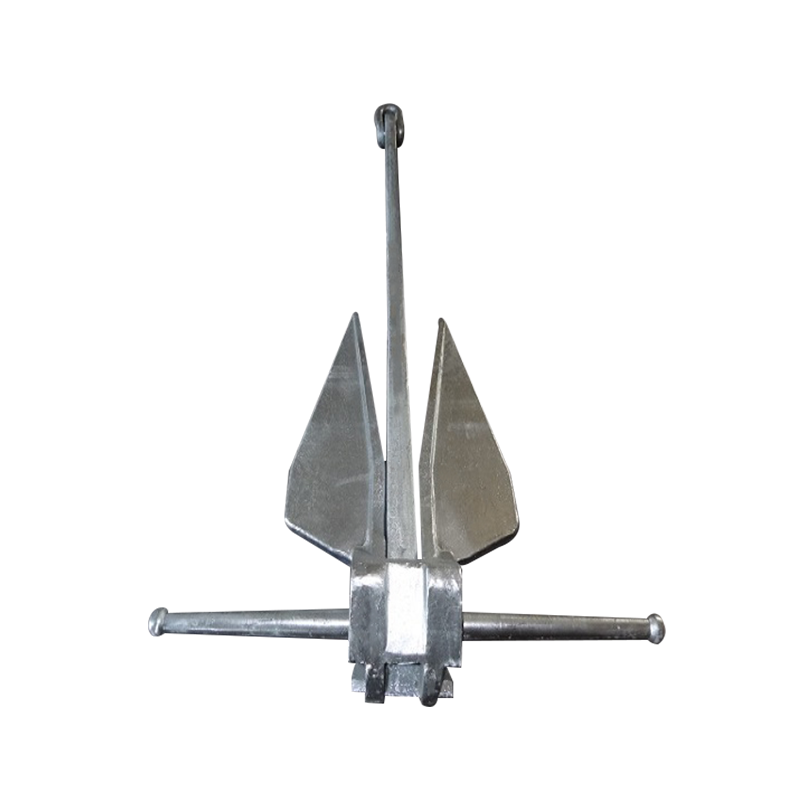

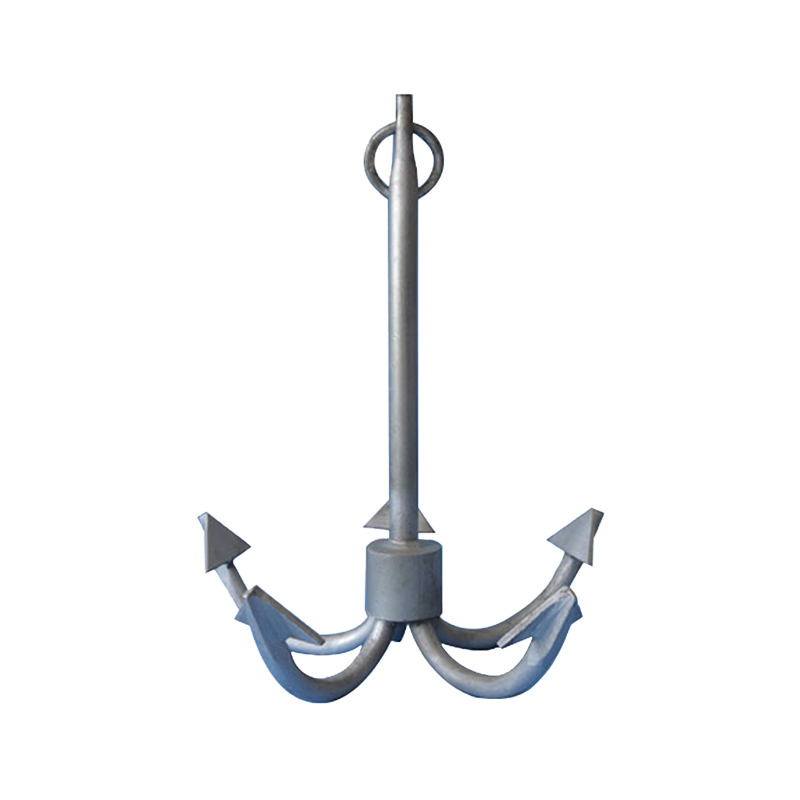

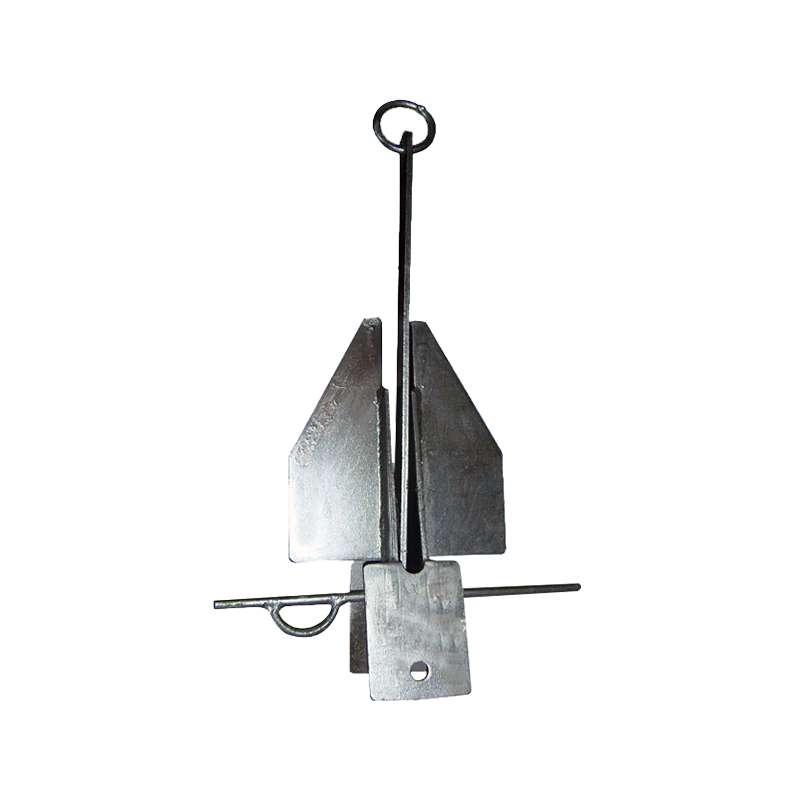

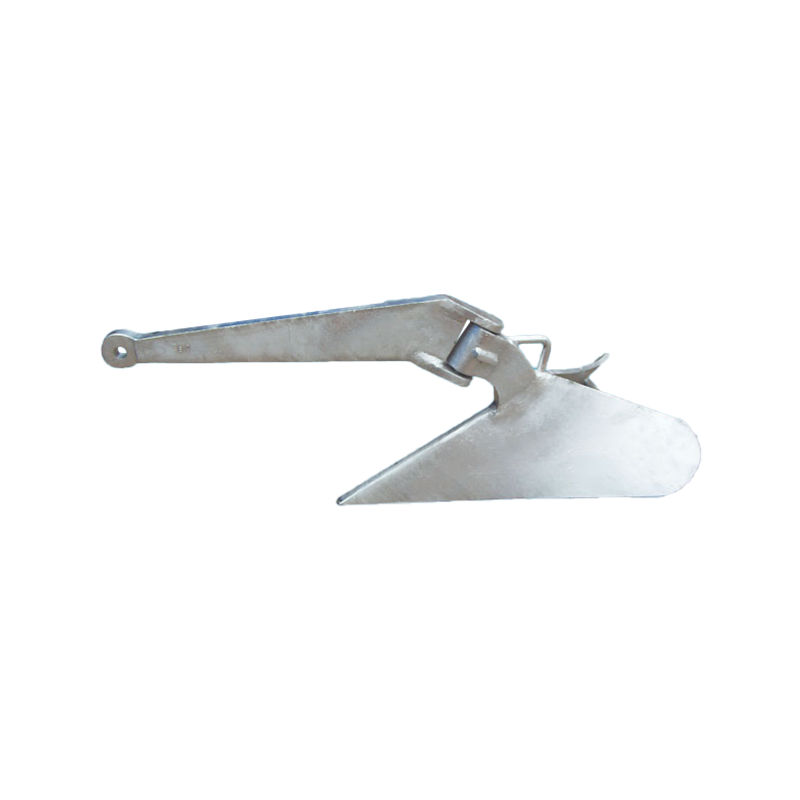

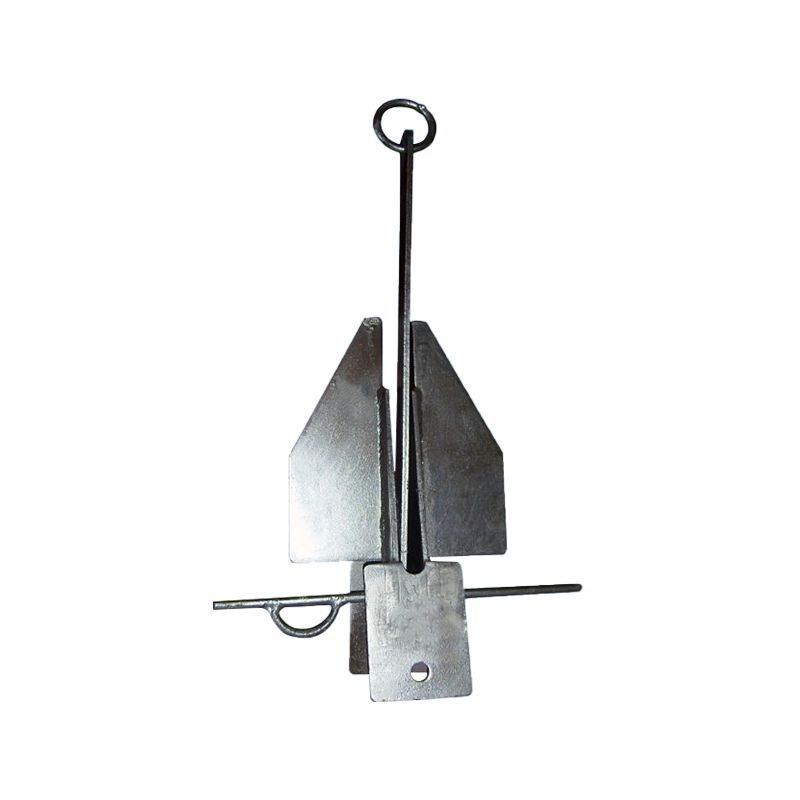

Yacht anchors are often subjected to tremendous forces, especially when the yacht is anchored in turbulent waters or exposed to strong winds. Hot-dip galvanization improves the overall strength of the anchor, making it more resilient to high loads and stresses. The zinc coating itself does not only serve as a protective barrier but also enhances the physical properties of the anchor’s material, providing greater tensile strength and improving the anchor’s load-bearing capacity. An HDG-treated anchor can withstand higher levels of strain without bending, breaking, or becoming deformed. This makes it especially important in challenging marine environments where yachts may encounter rough seas, strong tidal currents, or gusty winds. The ability of an HDG yacht anchor to handle significant forces directly impacts the yacht’s stability. If the anchor is strong enough to withstand these stresses, the yacht will remain secure in its moored position without the risk of dragging or breaking free. At Nantong Yangfan Marine Equipment Co., Ltd., we specialize in producing anchors that offer superior load-bearing capabilities. Our HDG yacht anchors are designed to provide optimal strength and durability, ensuring that they can handle the toughest conditions.

Durability is one of the key factors that yacht owners consider when selecting an anchor. Yacht anchors are regularly exposed to harsh conditions, including saltwater, extreme temperatures, and physical impacts. These factors can cause significant wear and tear on anchors that are not properly protected. Hot-dip galvanization ensures that the anchor retains its durability over time by forming a long-lasting protective coating that resists corrosion and wear. The durability of HDG yacht anchors also translates into fewer maintenance requirements. Traditional anchors made from untreated steel are prone to rust and corrosion, which means they require frequent cleaning, repainting, and sometimes even replacement. In contrast, HDG yacht anchors are designed to last longer without requiring extensive maintenance. The zinc coating prevents rust and deterioration, reducing the need for constant upkeep. This is particularly advantageous for yacht owners who prefer a low-maintenance anchoring solution that offers long-term reliability. Nantong Yangfan Marine Equipment Co., Ltd. focuses on providing yacht owners with anchors that offer both durability and low maintenance. Our HDG anchors provide superior resistance to the elements, reducing the frequency of repairs and replacements. The reduced need for maintenance not only saves yacht owners time and effort but also helps lower the long-term costs associated with anchoring systems.

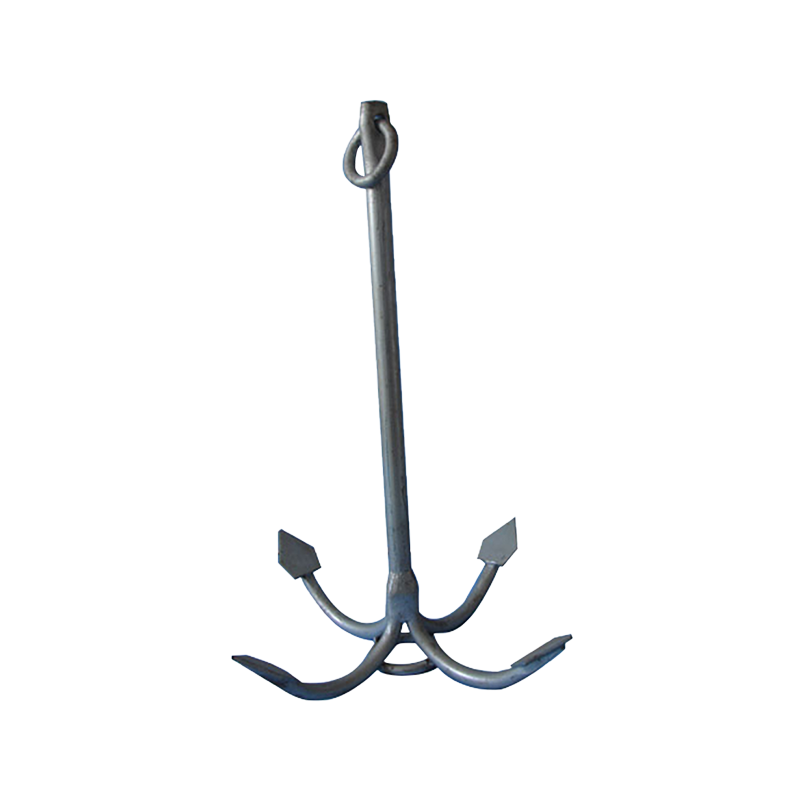

The stability of a yacht depends on several factors, one of the most important being the effectiveness of its anchoring system. A stable anchor ensures that the yacht remains in place, even when faced with shifting tides, high winds, or strong currents. HDG yacht anchors are designed to offer enhanced stability in various sea conditions. The galvanized coating allows the anchor to grip the seabed securely, preventing the yacht from dragging or becoming dislodged. The design and material properties of HDG yacht anchors enable them to anchor securely in both soft and hard seabed types, such as sand, mud, and rocky bottoms. The anchor's increased stability ensures that the yacht remains securely moored, even during rough weather conditions or when anchored for extended periods. At Nantong Yangfan Marine Equipment Co., Ltd., we understand the importance of stability in anchoring systems. Our HDG yacht anchors are specifically designed to provide maximum stability, ensuring that yachts remain securely anchored regardless of the sea conditions. Whether in calm waters or rough seas, our HDG anchors provide reliable performance, contributing to the overall stability of the yacht and enhancing safety during voyages.

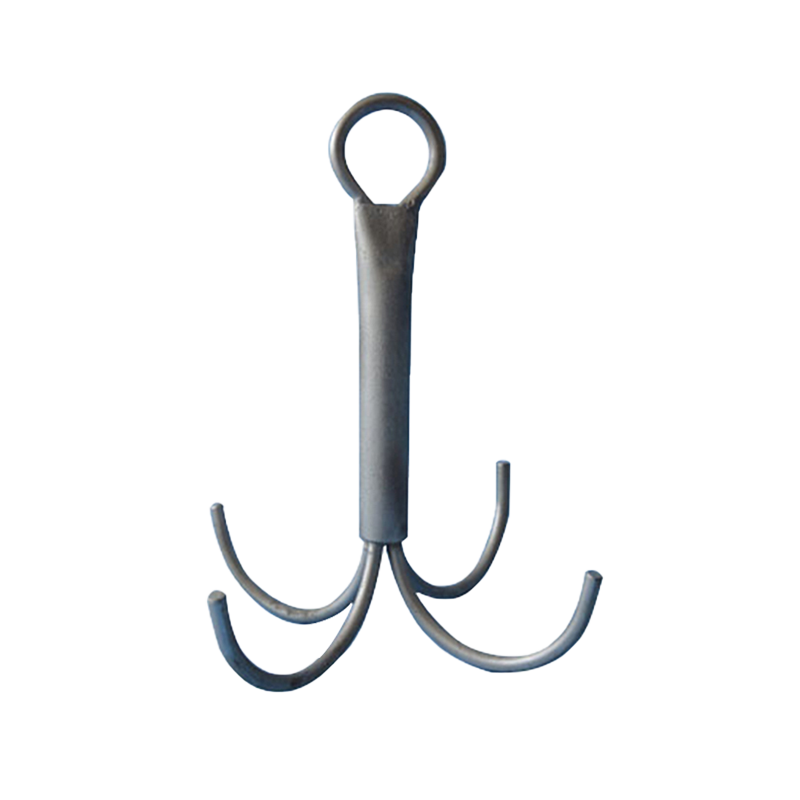

Anchors endure significant physical stress as they are deployed, retrieved, and subjected to impact with the seabed. Over time, this constant friction can cause wear and tear on the anchor, reducing its effectiveness and lifespan. HDG yacht anchors are designed to resist these types of wear and tear by providing an additional layer of protection. The zinc coating creates a hard, durable surface that helps prevent abrasions and other forms of physical damage during use. The enhanced surface hardness offered by the HDG process ensures that the anchor retains its shape and performance, even after frequent use. The resistance to physical damage also minimizes the risk of the anchor becoming damaged during handling or rough conditions. This increased durability translates into fewer repairs, extended anchor life, and better performance in the long run. At Nantong Yangfan Marine Equipment Co., Ltd., our HDG yacht anchors are built to withstand the rigors of regular use without succumbing to excessive wear and tear. By reducing the effects of friction and abrasion, we ensure that our anchors maintain their performance and structural integrity, contributing to a more reliable and effective anchoring system.

Handling and storing anchors can be cumbersome, especially when dealing with large, heavy equipment. However, the weight of an anchor must be carefully balanced to ensure that it is heavy enough to provide the necessary holding power but not so heavy that it becomes difficult to deploy or retrieve. The HDG process allows Nantong Yangfan Marine Equipment Co., Ltd. to produce yacht anchors that are optimized for weight and strength. The added zinc coating does not significantly increase the weight of the anchor, ensuring that it remains easy to handle while still providing excellent performance. HDG yacht anchors are designed to maintain an optimal weight-to-strength ratio, allowing yacht owners to easily deploy and retrieve the anchor without struggling with excessive weight. This balanced weight makes it easier to store the anchor on the yacht, reducing the space needed for storage and making it easier to access when needed. By producing lightweight yet robust HDG yacht anchors, we ensure that our clients experience less hassle when it comes to anchor handling and storage. Our commitment to optimizing the weight of our anchors means that yacht owners can easily manage their anchoring systems without compromising on performance or safety.

English

English 中文简体

中文简体