Application of Steel Cylindrical Buoys in Offshore Operations

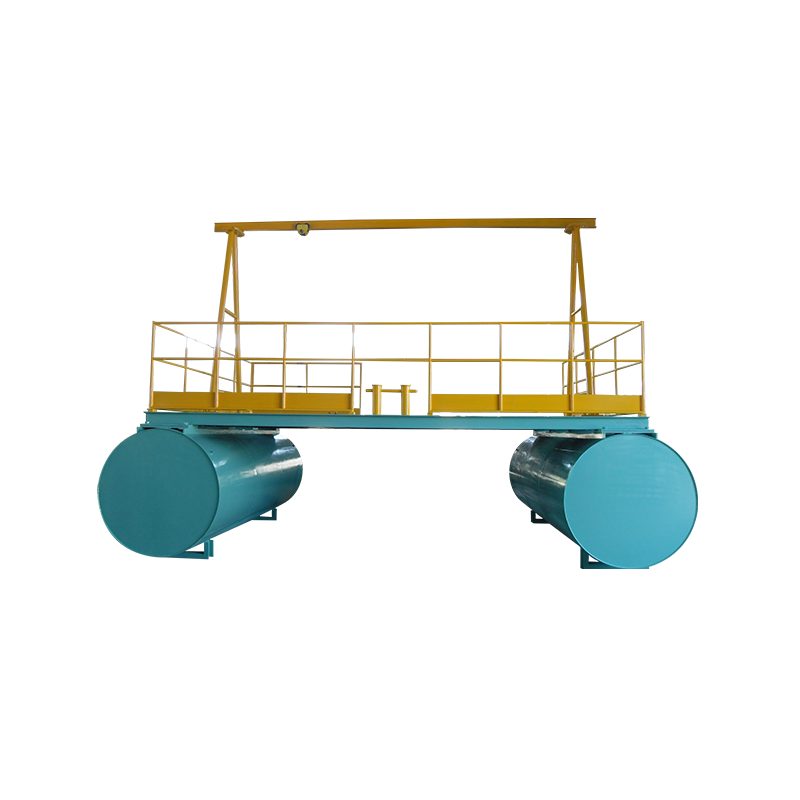

Steel cylindrical buoys are vital to the mooring systems used in offshore operations, particularly for large structures like oil platforms, floating production storage and offloading (FPSO) units, and even offshore wind turbines. These buoys serve as anchoring points for vessels, ensuring that floating platforms remain stationary despite challenging marine conditions, such as strong winds, waves, and tidal forces. The cylindrical shape of the buoy is not only ideal for minimizing resistance in ocean currents but also offers better stability by ensuring that the buoy remains upright even in turbulent water. The buoy's high-strength steel construction allows it to support significant loads without compromising its shape or stability. Special anti-corrosion surface treatments are applied to the steel to prevent degradation caused by saltwater, ensuring that the buoy remains functional and reliable for long periods. Nantong Yangfan Marine Equipment Co., Ltd. ensures that its steel cylindrical buoys meet rigorous performance standards, offering secure mooring solutions even in the most demanding offshore environments. By using advanced production techniques, these buoys are designed to provide continuous service, supporting a variety of offshore activities with minimal maintenance requirements. These mooring systems are designed for critical operations, such as ensuring the position of FPSOs in oil extraction activities or maintaining the location of floating wind turbines in energy generation projects. Steel cylindrical buoys ensure that these floating platforms remain fixed at precise coordinates, even during high-intensity weather events, which could otherwise cause instability. The durable steel construction guarantees that the buoys remain intact for extended periods, contributing to the overall safety of offshore infrastructure.

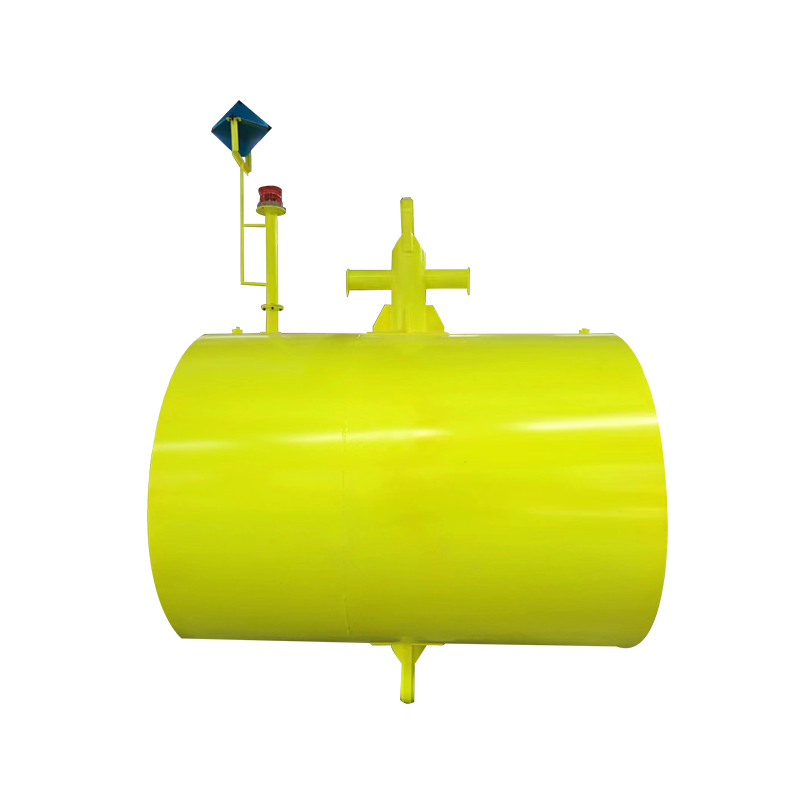

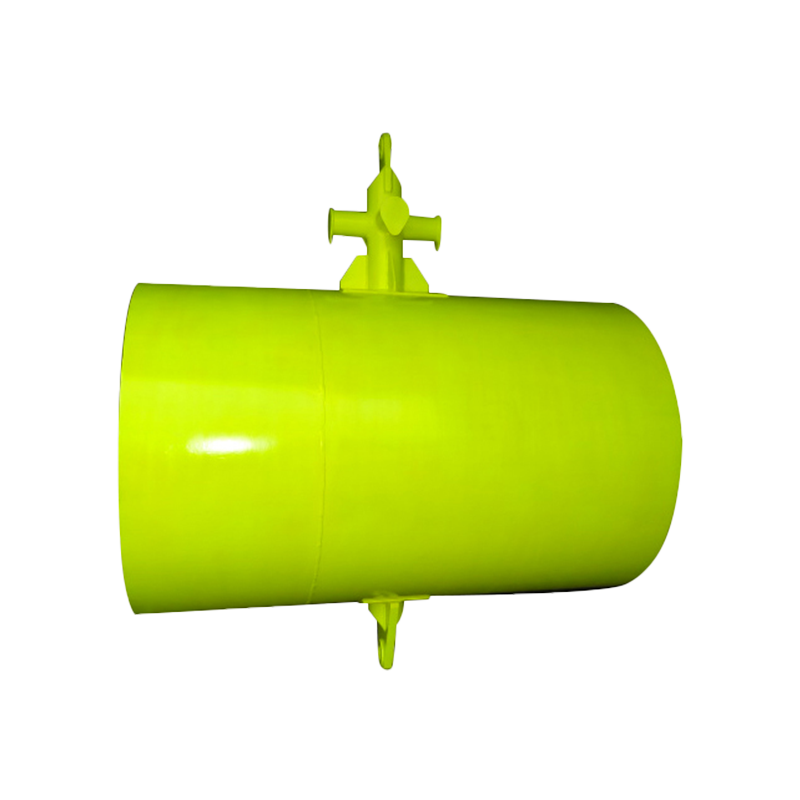

Steel cylindrical buoys play an important role in marking hazards and ensuring the safety of offshore operations. These buoys are deployed in areas with underwater hazards like reefs, submerged rocks, and shipwrecks that pose a threat to vessels navigating through the waters. These hazards can be a danger to shipping lanes, particularly in crowded offshore zones, making it imperative to mark such areas clearly. Steel cylindrical buoys, due to their height and stability, serve as prominent markers that help vessels navigate safely around these obstacles. In addition to their visibility above the waterline, these buoys are equipped with reflective materials or lights to enhance their visibility during both daytime and nighttime. The reflective materials or lights ensure that they remain visible to approaching vessels, even in low-light conditions. With Nantong Yangfan Marine Equipment Co., Ltd. producing these buoys with special coatings, the corrosion resistance of the steel ensures that these buoys will maintain their bright visibility without degradation over time. The advanced manufacturing techniques employed by the company ensure that the buoys are not only resistant to corrosion but also robust enough to withstand continuous exposure to rough seas, thereby maintaining their effectiveness as long-lasting hazard markers. Beyond marking immediate hazards, steel cylindrical buoys are also used to delineate safe navigation zones, such as the boundaries of restricted or regulated areas, preventing accidents and protecting both marine vessels and offshore workers. These buoys serve as beacons of safety in high-traffic marine zones, ensuring the smooth and safe operation of vessels traveling through busy offshore regions.

In offshore and coastal waters, steel cylindrical buoys are widely used as integral navigation aids. These buoys serve as reference points for vessels to navigate accurately, particularly when entering or leaving ports, harbors, or offshore installations. They mark safe passage routes and help avoid areas of danger, such as shallow reefs or restricted zones. Given the challenging conditions of offshore environments—where traditional, fixed navigation aids may not be feasible or safe—steel cylindrical buoys provide a highly reliable and flexible solution for marine navigation. The cylindrical design of the buoy ensures that it remains stable even in rough seas. Its buoyant nature means it stays afloat while remaining visible above the waterline, regardless of tide changes or current shifts. The steel construction provides the necessary strength to withstand the continuous force of waves and wind, ensuring the buoy's position is maintained over time. Steel cylindrical buoys can also be equipped with advanced technologies like GPS systems, sensors, and lights, improving their functionality and reliability. The integration of these technologies helps enhance navigation accuracy, especially for vessels operating in low-visibility conditions or during the night. Nantong Yangfan Marine Equipment Co., Ltd. manufactures buoys that are designed with precision to meet both local and international maritime standards. Their steel cylindrical buoys ensure that they can withstand the pressures of offshore environments while providing a safe and consistent navigation reference. The buoys’ high resistance to corrosion, even in the harshest saltwater conditions, ensures that they remain operational for long durations, contributing to safe and efficient maritime transport.

Steel cylindrical buoys are also commonly used in offshore operations to mark the location of underwater pipelines and cables. These structures are critical for the transport of energy, gas, and telecommunications between offshore platforms and land-based facilities. Since pipelines and cables are often laid along the seabed in areas of high traffic or unpredictable conditions, it is vital to clearly mark their locations to prevent accidental damage from anchors, dredging, or fishing operations. Steel cylindrical buoys provide a highly effective means of marking the locations of these critical subsea infrastructures. These buoys are equipped with technology that can alert marine operators to the exact location of underwater pipelines or cables, preventing collisions and reducing the risks of damage. The durability and corrosion resistance of the steel ensure that the buoys remain intact even after long exposure to saltwater and constant wave movement. Nantong Yangfan Marine Equipment Co., Ltd. ensures that its steel buoys are manufactured with long-term durability in mind, providing a safe and reliable marking solution for offshore infrastructure. The buoys are also useful in areas where pipelines or cables may be buried or where seabed conditions make it difficult to detect their position.

The development of offshore renewable energy sources, such as wind and tidal energy, has rapidly expanded in recent years. Steel cylindrical buoys play an essential role in supporting these energy-producing structures, including floating wind turbines and tidal energy generators. These buoys are used to anchor the floating platforms or turbines to the seabed, ensuring that the equipment remains stationary despite the influence of strong currents, wind, and waves. The use of steel cylindrical buoys in offshore renewable energy projects is crucial due to their robustness and long-lasting performance. The ability to withstand harsh weather conditions is particularly important in renewable energy installations that are often located far offshore, where access for maintenance is limited. Steel cylindrical buoys, manufactured by Nantong Yangfan Marine Equipment Co., Ltd., offer exceptional corrosion resistance, ensuring that they can remain operational for extended periods without significant degradation. Their design allows them to remain stable in turbulent marine environments, ensuring that offshore energy platforms maintain their performance and safety standards. In the case of floating wind turbines, these buoys provide stability, preventing the turbine from moving excessively due to wind or tidal forces. The buoys’ surface treatments and high-strength steel construction ensure that they endure even in the challenging offshore environment, contributing to the overall reliability of renewable energy generation systems.

English

English 中文简体

中文简体