Advantages of Using Concrete Mooring Sinkers in Offshore Operations

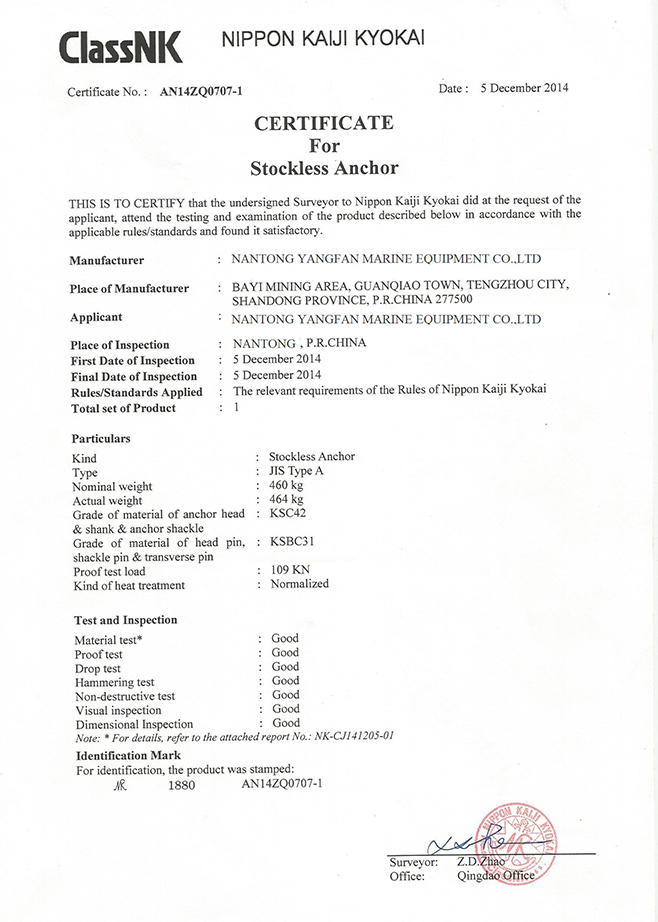

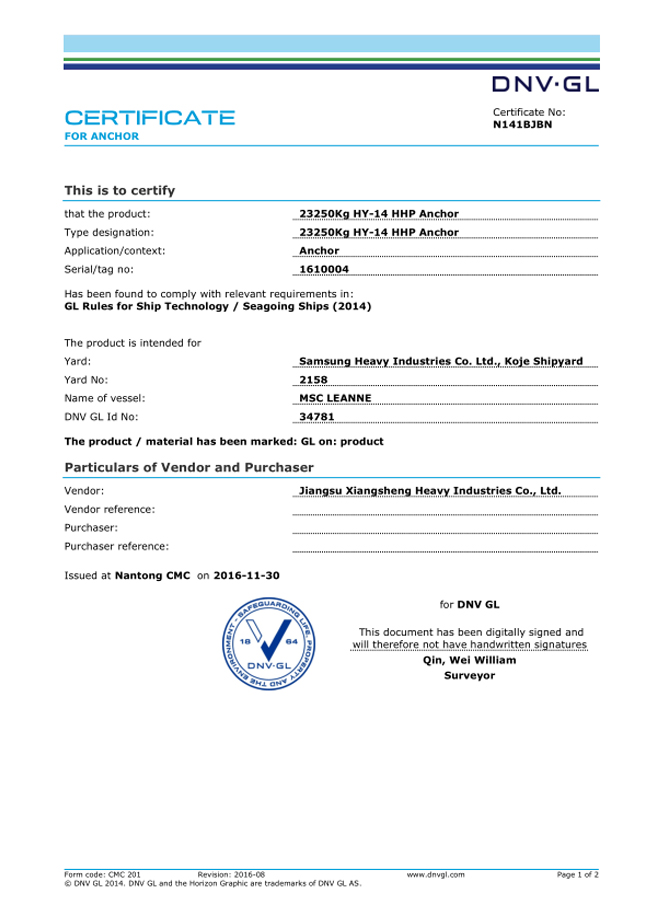

Concrete mooring sinkers offer a highly cost-effective solution compared to alternative mooring systems made of more expensive materials such as metals or specialized alloys. The raw materials for concrete are abundant and inexpensive, which significantly reduces the overall production cost. Unlike metal-based sinkers, which require additional processes like galvanization or coating to prevent corrosion, concrete’s natural resistance to corrosion means that additional maintenance expenses are minimized. Another key cost-saving factor is the reduced transportation and installation cost. Due to concrete’s high density, fewer sinkers are required to provide the same weight and stability as other materials. This efficiency in material usage leads to reduced shipping and handling expenses, particularly for large-scale projects where a large number of sinkers are needed. Concrete mooring sinkers have a longer lifespan than other materials, contributing to lower long-term costs. While metal mooring solutions may require frequent replacement or maintenance, concrete mooring sinkers can remain functional for many years without degradation in performance. Their resistance to corrosion and wear means that offshore operations benefit from a durable solution, reducing the frequency and cost of replacements. At Nantong Yangfan Marine Equipment Co., Ltd., we focus on providing our clients with affordable solutions that don’t compromise on quality or reliability. By using concrete as the primary material for our mooring sinkers, we ensure that our products meet the performance needs of offshore projects while keeping costs manageable.

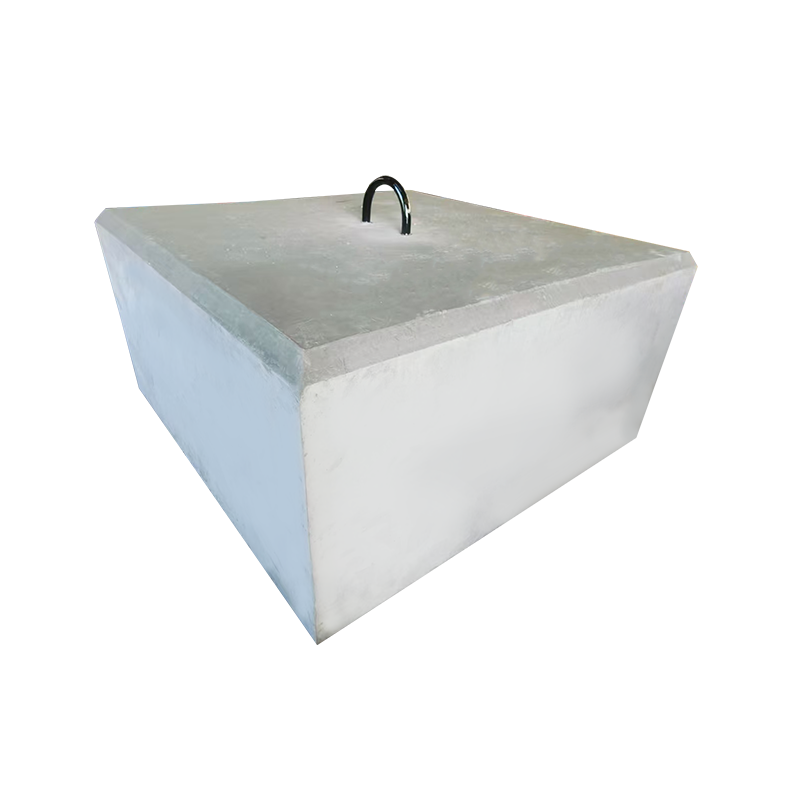

Concrete is known for its incredible durability, especially when exposed to the harsh conditions of the marine environment. Unlike metal-based mooring systems, which are prone to rust, corrosion, and other forms of wear over time, concrete remains stable and intact for extended periods. The exposure to seawater does not affect its structural integrity, and it doesn’t require constant monitoring or maintenance to ensure functionality. This durability is essential for offshore operations, where maintaining the stability of vessels and structures is paramount to ensuring safety and minimizing operational disruptions. In addition to corrosion resistance, concrete mooring sinkers are designed to withstand physical stressors such as extreme weather, powerful tides, and ocean currents. These physical forces can cause damage to poorly designed or fragile mooring systems. However, concrete’s robustness ensures that mooring sinkers remain firmly in place, withstanding forces that could cause less durable materials to fail. The longevity of concrete mooring sinkers means that they can be relied upon for years, minimizing the need for costly repairs or replacements. While some mooring systems require periodic servicing or replacements due to wear, concrete sinkers maintain their functionality without regular maintenance, thus reducing the overall costs of operation. At Nantong Yangfan Marine Equipment Co., Ltd., we design our concrete mooring sinkers to withstand even the most challenging offshore conditions. By combining advanced manufacturing processes and high-strength concrete materials, we ensure that our products offer long-lasting performance for our clients’ operations.

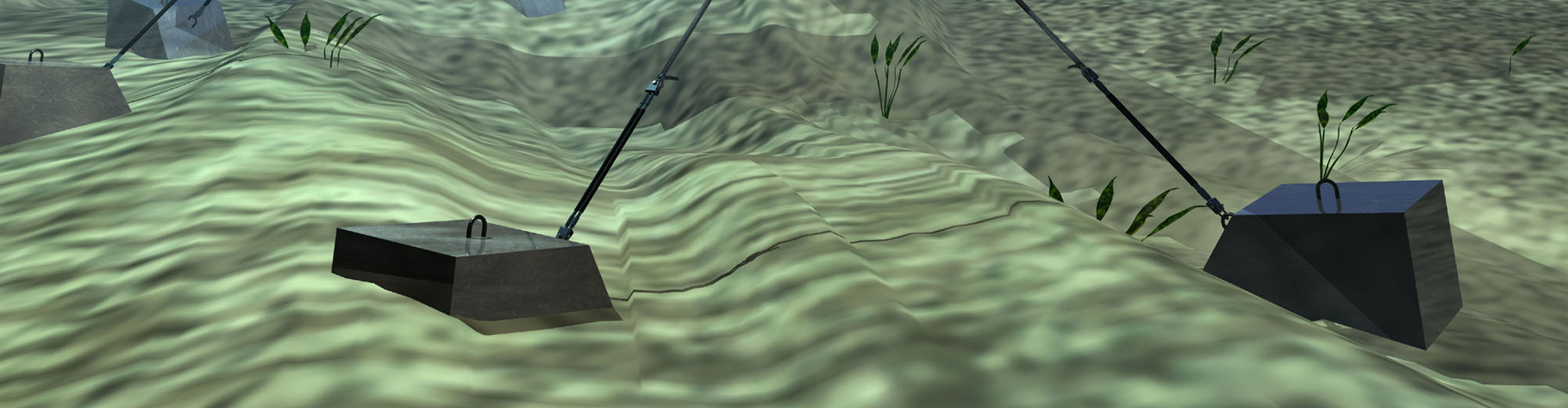

One of the main purposes of concrete mooring sinkers is to provide a heavy, stable anchor for offshore vessels, buoys, and platforms. The high weight of concrete ensures that these sinkers can effectively counterbalance the forces exerted on mooring lines by wind, waves, and currents. This weight-bearing capacity helps maintain the stability of marine structures, preventing them from drifting or becoming unmoored during harsh weather conditions. The stability of concrete mooring sinkers is also enhanced by their design. The heavy, compact shape of the sinkers ensures that they sink quickly to the seabed, settling firmly in place. This minimizes the risk of the sinker shifting or dragging along the seafloor, which could compromise the stability of the vessel or platform it is mooring. The unique weight distribution of concrete also prevents tilting or wobbling, which could reduce the effectiveness of the mooring system. In offshore operations, stability is crucial. Unstable mooring can lead to damage to both the vessel and the mooring system itself, resulting in costly repairs and downtime. By providing superior weight and stability, concrete mooring sinkers ensure that offshore operations are safe and reliable, allowing marine structures to remain secure even under extreme conditions. At Nantong Yangfan Marine Equipment Co., Ltd., our concrete mooring sinkers are designed to deliver superior stability and weight-bearing capacity. This allows our clients to rely on a durable and stable mooring solution that minimizes the risk of accidents and operational interruptions.

Concrete mooring sinkers are an environmentally friendly solution compared to metal or plastic alternatives, which can have a more significant environmental impact. Concrete is a natural material that does not leach harmful chemicals or toxins into the marine environment, unlike some synthetic materials that can degrade and pollute the water. This makes concrete mooring sinkers a safer choice for environmentally-conscious operations. The durability of concrete mooring sinkers reduces the need for frequent replacements, reducing waste. When used properly, concrete sinkers can remain effective for many years, meaning fewer resources are used over the course of an offshore operation. This reduces the environmental footprint associated with manufacturing, transporting, and disposing of mooring equipment. The inert nature of concrete also means that it does not degrade into harmful particles that could damage marine ecosystems. Other materials, especially those that rely on coatings or galvanization, can sometimes cause pollution when they break down or degrade. By choosing concrete mooring sinkers, offshore operations can reduce their impact on the surrounding environment. At Nantong Yangfan Marine Equipment Co., Ltd., we are dedicated to producing products that not only perform well but also contribute to environmental sustainability. Our concrete mooring sinkers are designed with minimal environmental impact in mind, helping to preserve the health of marine ecosystems.

Another advantage of concrete mooring sinkers is their simplicity and ease of handling during transportation and installation. The pre-cast nature of concrete mooring sinkers means that they arrive on-site ready for immediate installation, eliminating the need for complicated assembly or adjustments. This reduces the time and labor required for installation, allowing offshore operations to proceed more efficiently. Concrete’s high density also makes it easier to transport fewer units to achieve the desired weight and anchorage strength. This improves logistics and reduces the cost and complexity of transportation, especially in large-scale projects where many sinkers are required. Concrete mooring sinkers are also relatively simple to handle and position, even in rough seas, due to their stable, compact nature. By simplifying the installation process, concrete mooring sinkers reduce the overall time spent setting up and ensure faster project completion. The quick and efficient installation process is particularly advantageous in offshore environments where operational downtime must be minimized. At Nantong Yangfan Marine Equipment Co., Ltd., we focus on providing our clients with easy-to-install concrete mooring sinkers that streamline offshore operations. Our products are designed for simple handling and installation, allowing for quicker deployment and reducing overall project costs.

Concrete mooring sinkers are incredibly versatile and can be used in a wide range of offshore applications. From commercial shipping vessels to oil platforms, recreational boats, and marine buoys, concrete mooring sinkers can effectively anchor a variety of marine structures. Their weight and stability make them suitable for both shallow coastal waters and deeper offshore environments. The design and size of concrete mooring sinkers can also be customized to meet specific operational requirements. Depending on the weight and size of the structure being moored, concrete sinkers can be tailored to provide the optimal amount of stability and security. This versatility allows for greater flexibility in offshore operations, ensuring that the mooring system meets the unique needs of each project. Concrete sinkers are also adaptable to different seabed types, such as sand, mud, or rock, further enhancing their versatility. The ability to maintain stability across various marine environments makes concrete mooring sinkers an essential tool for diverse offshore operations. At Nantong Yangfan Marine Equipment Co., Ltd., we offer a wide range of concrete mooring sinkers to meet the needs of various offshore applications. Our products are customizable to provide the optimal solution for each specific project, ensuring that our clients receive the best possible performance.

English

English 中文简体

中文简体