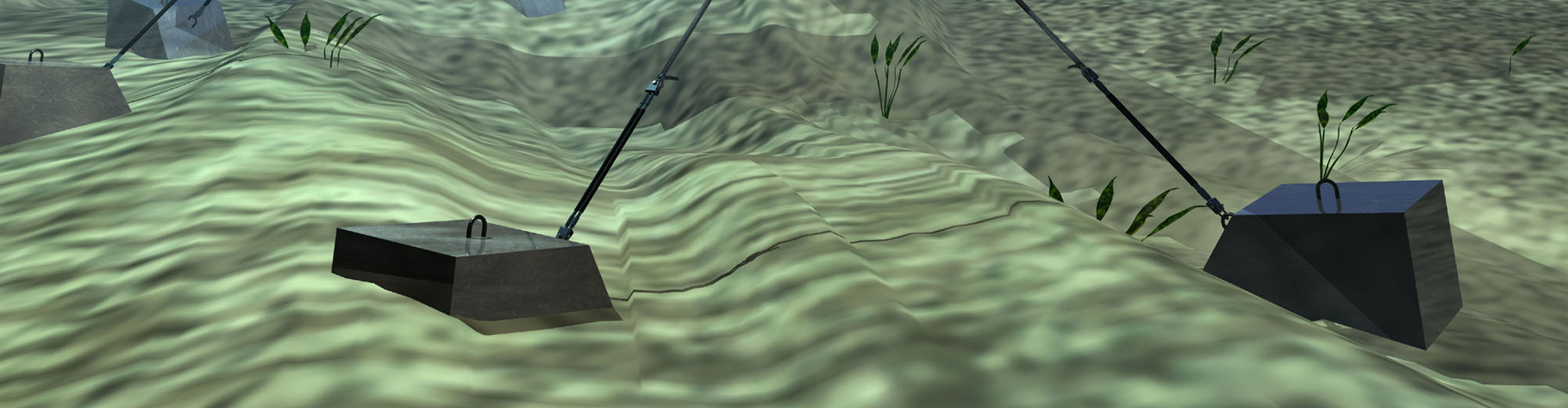

Marine ports and harbors serve as critical hubs for global shipping, where large vessels such as oil tankers, cargo ships, and container vessels regularly dock. Securing these large ships to prevent movement during both docking and while waiting at the port is a fundamental aspect of port operations. Without reliable mooring systems, the risks of drifting vessels, collisions, and other safety issues increase significantly. Cast iron mooring sinkers provide a stable, secure, and effective anchoring solution to ensure vessels are safely moored. The heavy weight of cast iron sinkers makes them ideal for keeping large vessels stationary, even in areas with strong tidal currents or turbulent weather conditions. By utilizing a high-density material, cast iron ensures that the mooring system works efficiently to hold the vessel in place. This is especially important for vessels that have large surface areas and are susceptible to drifting due to the influence of wind and waves. Cast iron mooring sinkers are placed at strategic points within the harbor or docking area, where they can provide the necessary resistance against forces that attempt to move the ship. These sinkers can either be deployed as part of a fixed mooring system or used in temporary mooring setups depending on the needs of the port. Their corrosion resistance ensures that they maintain their functionality even after long periods of exposure to saltwater and other harsh environmental conditions. At Nantong Yangfan Marine Equipment Co., Ltd., we provide a range of cast iron mooring sinkers designed for large vessels in ports and harbors. Our products are engineered to deliver consistent performance over time, offering a dependable solution for docking and securing vessels, thus enhancing port safety and operational efficiency.

Offshore oil and gas platforms operate in some of the world’s most challenging environments. They face strong tidal forces, aggressive weather conditions, and the risk of severe storms, all of which require robust and reliable mooring systems to ensure stability and safety. Cast iron mooring sinkers are frequently used in these offshore applications due to their high-density, corrosion-resistant properties, and ability to withstand high-pressure environments. When it comes to floating offshore oil platforms, securing these structures to the seabed is crucial. The platforms need to remain stationary to ensure proper operation of the equipment and the safety of the personnel onboard. Cast iron mooring sinkers, with their ability to provide a concentrated weight, can anchor these platforms even in the deepest parts of the ocean, where traditional anchoring solutions may not be effective. The installation of cast iron mooring sinkers in offshore oil and gas operations ensures that platforms stay secured despite the powerful forces exerted by the surrounding water. These sinkers hold the platform in place during both calm and stormy conditions, preventing drift or movement. Cast iron's excellent compressive resistance also ensures that the sinkers do not deform under pressure, providing long-term stability and reliability. At Nantong Yangfan Marine Equipment Co., Ltd., we specialize in providing high-quality mooring solutions for offshore oil and gas platforms. Our cast iron mooring sinkers are tailored to meet the rigorous demands of this industry, ensuring that these platforms remain stable and operational even in the most extreme environments.

Yachts and recreational boats also require reliable mooring solutions to ensure their security while docked or moored in open water. While yachts may not face the same environmental challenges as large ships or offshore platforms, they still need effective anchoring systems to remain stationary, especially during adverse weather conditions such as storms or high winds. Cast iron mooring sinkers offer an ideal solution for recreational vessels, providing a combination of cost-efficiency, durability, and effective anchoring. For private yacht owners or marina operators, securing the vessel to the seabed is critical to prevent drifting and ensure safety while at anchor. Cast iron mooring sinkers' high density allows them to provide a stable foundation, holding the yacht in place even when wind and waves threaten to displace the vessel. Cast iron’s resistance to corrosion ensures that the sinkers perform well in saltwater conditions without degrading over time. In recreational marine operations, cast iron mooring sinkers are used in smaller-scale mooring systems, such as those found in marinas or for boats that are anchored in remote locations. The weight of the sinkers is balanced with the size and type of vessel being secured, ensuring that the anchor system provides just the right amount of holding power to prevent the boat from drifting. Nantong Yangfan Marine Equipment Co., Ltd. produces cast iron mooring sinkers that are suitable for recreational boating needs, offering reliable and effective anchoring solutions that can withstand the challenges of both recreational and commercial marine environments.

As the demand for renewable energy grows, offshore wind farms have become an increasingly common sight in many coastal regions. Floating wind farms, in particular, require secure and stable mooring systems to keep the wind turbines in place. These floating platforms are subject to powerful winds and ocean currents, which could cause instability if not anchored properly. Cast iron mooring sinkers are commonly used in these applications due to their strength and corrosion resistance. Floating wind farms rely on mooring systems to maintain the position of each floating platform, ensuring that the turbines can capture wind energy efficiently without the risk of drifting or misalignment. Cast iron mooring sinkers provide the necessary weight and stability to keep these platforms anchored securely to the seabed. Their high-density properties make them an effective solution in deepwater locations where anchoring solutions need to withstand substantial oceanic forces. The use of cast iron mooring sinkers in renewable energy applications contributes to the sustainability of these operations. Cast iron is a recyclable material, and the durability of these mooring systems reduces the need for frequent replacements, thus contributing to the long-term sustainability of offshore wind farms. At Nantong Yangfan Marine Equipment Co., Ltd., we offer advanced solutions for floating wind farms and marine renewable energy projects. Our cast iron mooring sinkers are designed to ensure the stability of these structures, supporting the global shift toward sustainable energy production.

Offshore aquaculture and marine cultivation projects have become increasingly prevalent as the world seeks sustainable solutions for food production. These projects often require the use of floating nets and structures that must be anchored securely to prevent displacement caused by strong currents, high winds, or storms. Cast iron mooring sinkers provide an ideal solution for anchoring these floating systems, offering both cost-effectiveness and durability. In offshore aquaculture operations, the stability of the mooring system is vital for the successful growth of fish, shellfish, or other marine organisms. If the mooring system fails, the entire operation can be compromised, resulting in significant financial losses. Cast iron mooring sinkers, with their high-density design and corrosion resistance, offer the strength needed to secure these systems, ensuring they stay in place regardless of changing environmental conditions. For seaweed farming and other marine cultivation projects, the ability to secure equipment and infrastructure in deepwater locations is equally important. Cast iron mooring sinkers, paired with other marine equipment, provide the necessary anchorage to ensure that cultivation systems remain stable and productive. Nantong Yangfan Marine Equipment Co., Ltd. manufactures cast iron mooring sinkers designed to meet the specific needs of offshore aquaculture and marine cultivation. Our products ensure that these operations remain stable and safe, maximizing productivity and minimizing risks.

English

English 中文简体

中文简体