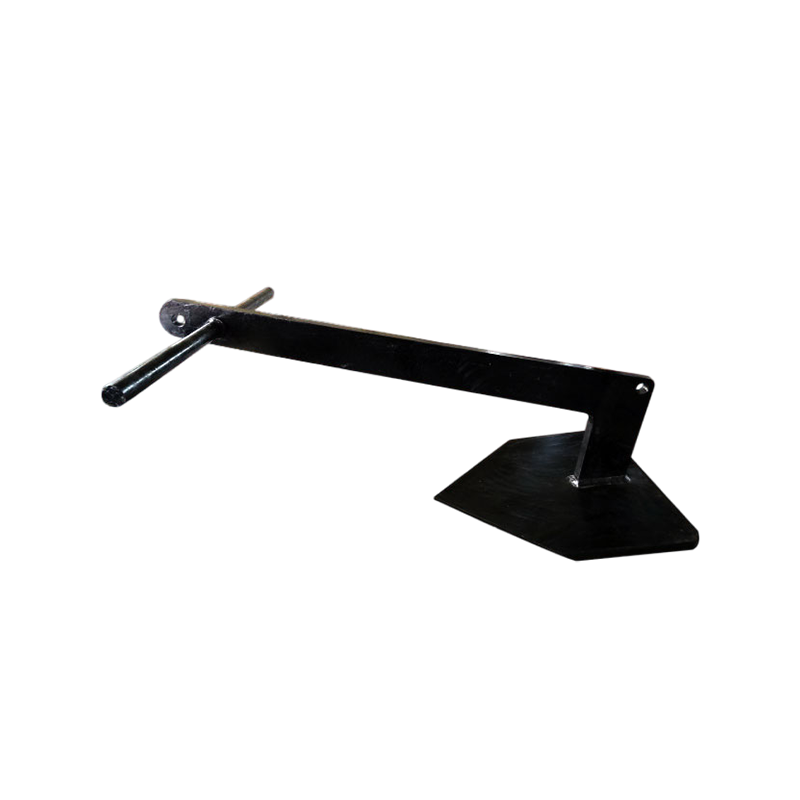

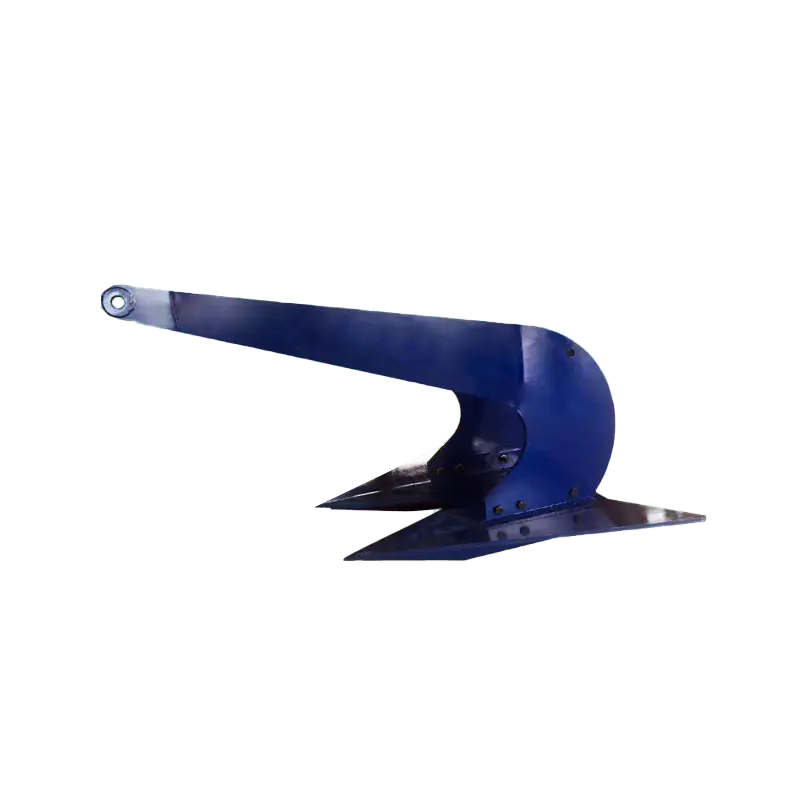

1. Aquaculture Mooring Anchors: Essential Components for Aquaculture Systems

Aquaculture mooring anchors play a pivotal role in the stability of aquaculture systems, ensuring that key equipment such as cages, buoys, and platforms remain securely fixed in place despite constantly changing environmental conditions. These anchors must provide strong pulling force and stability to withstand pressures from water currents, tidal shifts, waves, and wind. As such, they need to be designed with advanced engineering and high-quality materials to handle the demanding marine environment.

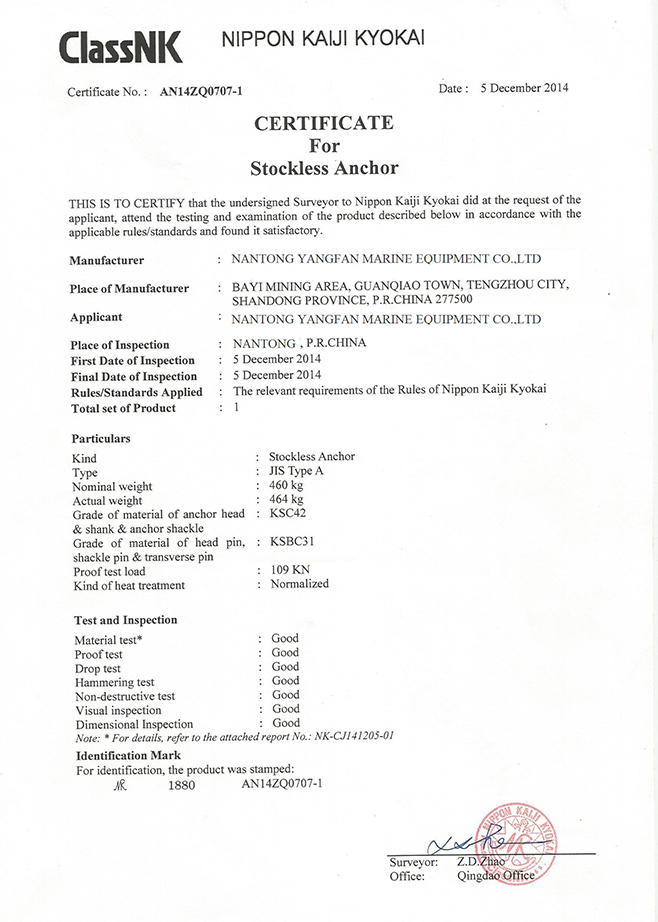

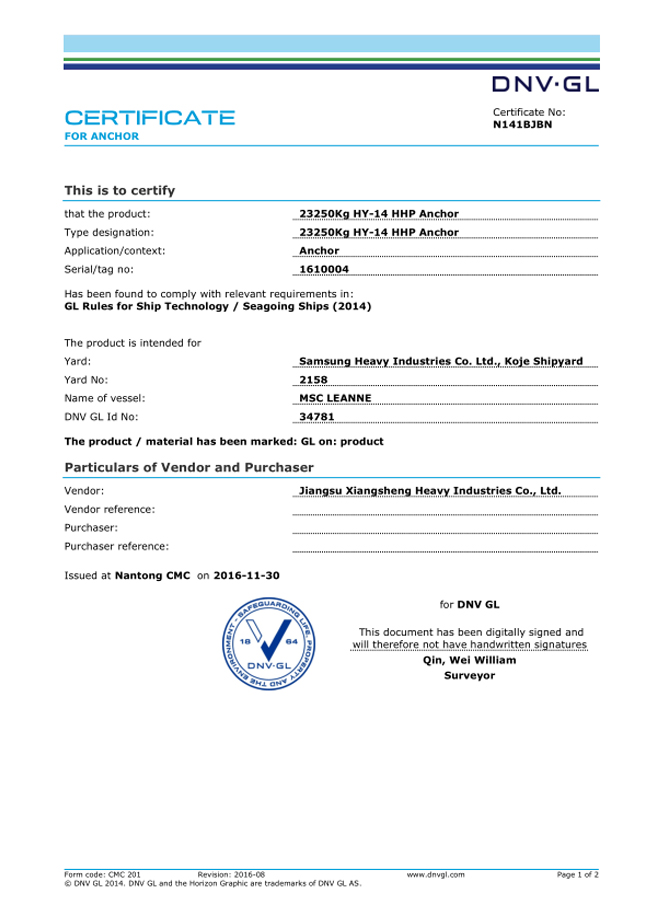

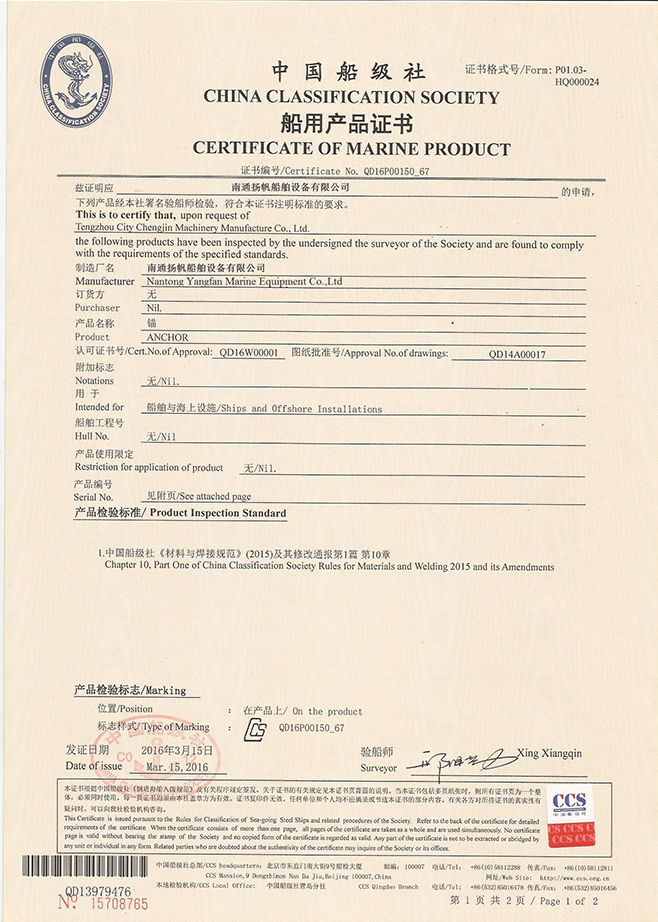

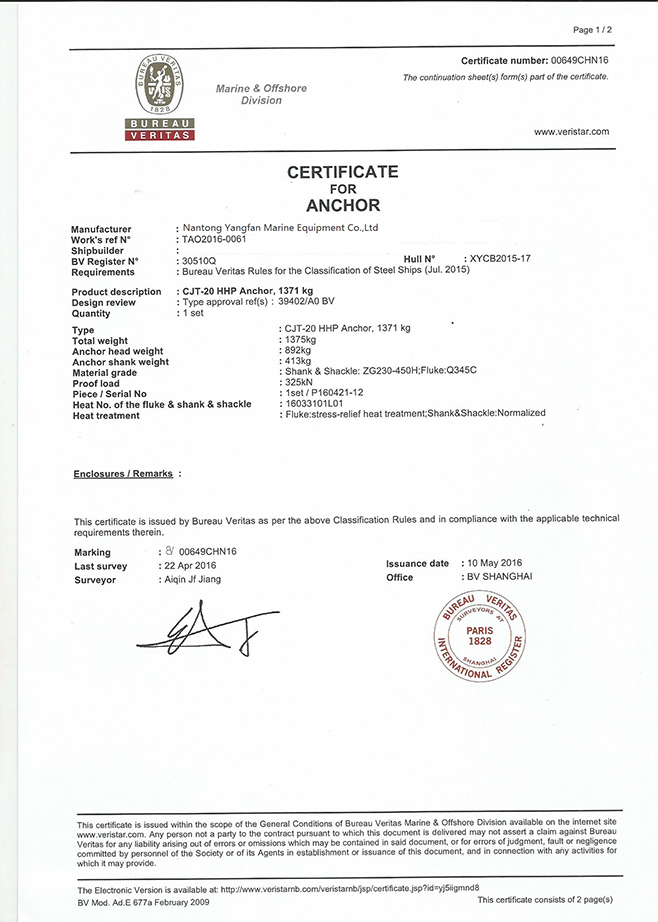

At Nantong Yangfan Marine Equipment Co., Ltd., we specialize in manufacturing high-performance mooring anchors that meet the rigorous standards required for modern aquaculture. With our extensive experience in marine equipment manufacturing, we understand the critical role anchors play in maintaining operational efficiency. Without proper mooring, aquaculture infrastructure is at risk of shifting or being displaced, which could disrupt the entire production cycle. This not only causes financial losses but also poses a risk to marine ecosystems and the safety of aquatic life.

Our anchors are designed to accommodate the unique challenges of various aquaculture systems. For instance, they are engineered to secure fish cages in open waters, where currents and wave action are unpredictable. Our products are tailored to ensure maximum stability, offering a reliable and durable solution to the complexities faced in large-scale aquaculture operations. Whether for offshore fish farming, shellfish cultivation, or floating net cages, our anchors are integral to the success of these systems.

At Nantong Yangfan Marine Equipment Co., Ltd., we combine cutting-edge manufacturing technologies with high-quality materials to deliver products that enhance both the operational efficiency and safety of aquaculture operations. Our production capacity includes more than 5,000 tons annually, supported by a skilled team of 80 employees, including 10 professional technicians and 5 engineers, ensuring the precision and reliability of every product.

2. Durability and Corrosion Resistance in Harsh Marine Environments

One of the most critical challenges in aquaculture mooring systems is the corrosive nature of the marine environment. Saltwater, temperature fluctuations, and the constant exposure to wind and waves can quickly degrade materials, compromising the integrity of anchors and other marine equipment. For this reason, ensuring that aquaculture mooring anchors are built to withstand corrosion is essential for the long-term success of aquaculture operations.

At Nantong Yangfan Marine Equipment Co., Ltd., we utilize only the highest-quality corrosion-resistant materials, including hot-dip galvanized steel and stainless steel, to manufacture our mooring anchors. These materials are specifically chosen for their ability to endure the harsh conditions of the marine environment. Hot-dip galvanization, for instance, provides an additional layer of protection, ensuring that the anchor can resist rust and corrosion even in the most challenging environments. Stainless steel, known for its superior resistance to saltwater corrosion, ensures that our anchors maintain their structural integrity throughout their service life.

Our production facility is equipped with state-of-the-art equipment, such as laser cutting machines, electric welding machines, and advanced testing systems, enabling us to create products that not only meet but exceed industry standards. Our annual production capacity of over 5,000 tons allows us to deliver both standard and customized mooring anchors to meet the diverse needs of our clients. Each anchor undergoes rigorous quality control processes, including tensile testing, magnetic particle flaw detection, and salt testing, ensuring that all products are reliable and durable.

The corrosion-resistant properties of our mooring anchors reduce the need for frequent maintenance and replacements, which is a significant cost-saving factor for aquaculture businesses. Additionally, by reducing the frequency of anchor replacements, we also help minimize the environmental impact of disposal and waste, further supporting sustainable practices within the industry.

3. Minimizing Ecological Impact and Enhancing Sustainability

Sustainability is becoming an increasingly important consideration in the aquaculture industry. As more aquaculture farms are established in marine environments, it is essential to ensure that the infrastructure used does not harm the surrounding ecosystem. Aquaculture mooring anchors, if not designed with care, can have a significant negative impact on marine life, disturbing the seabed and threatening biodiversity.

At Nantong Yangfan Marine Equipment Co., Ltd., we prioritize the ecological impact of our products. Our mooring anchors are designed with the environment in mind, ensuring that they have minimal disruption to the surrounding aquatic ecosystem. For example, we incorporate features that reduce the risk of disturbing the seafloor, such as anchors with smoother surfaces that minimize sediment disturbance. We also work with materials that are less likely to cause long-term environmental harm, such as using bio-degradable coatings and innovative designs that reduce the physical footprint of the anchor.

Our approach to eco-friendly design extends beyond the materials we use. We also incorporate advanced engineering practices to reduce the overall drag of mooring systems, which can reduce energy consumption and wear on the equipment. This not only makes our anchors more environmentally friendly but also improves their overall efficiency. By using the latest technological advancements, Nantong Yangfan Marine Equipment Co., Ltd. is at the forefront of designing mooring anchors that contribute to sustainable aquaculture practices.

To ensure that our products meet the highest standards of sustainability, we employ a comprehensive testing process that includes non-destructive testing, geometric dimension checks, and salt testing, among others. Our testing equipment, such as universal tensile testing machines, magnetic particle flaw detectors, and roughness gauges, guarantees that every product we produce meets or exceeds international environmental and quality standards. By focusing on sustainability, we help our customers reduce their carbon footprint while ensuring the long-term viability of their aquaculture operations.

English

English 中文简体

中文简体